OUR TECHNOLOGY

CORPORATE

OUR TECHNOLOGY

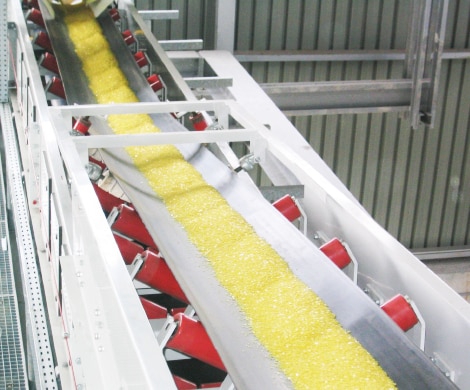

PREMIUM QUALITY FORMING

Where processing takes place close to a refinery, sulphur can usually remain in its molten form.

The molten sulphur generally comes from Claus process, which converts H2S into elemental sulphur with the resultant properties:

- Temperature: 145 – 150 °C

- Purity: > 99,9%

- H2S: < 10 ppm

But when greater distances are involved and certainly when elemental sulphur is to be shipped from one continent to another – it needs to be solidified.

It was in order to establish standards for formed sulphur – and its suitability for transportation (i.e. export) – that, in the late 1970s, SUDIC (Sulphur Development Institute of Canada) set about defining what has now become globally recognized as a ‘premium’ quality product.

In determining this quality, SUDIC looked at friability and fines content, both critical to efficient, clean and environmentally safe production and handling. The other major factor was moisture content; excess moisture not only adds weight, leading to unnecessary transportation and remelting costs, but also results in increased acidity, causing corrosion in conveyors, silos, trucks, rails cars and ship holds. A ‘wetter’ product is also more susceptible to freezing into lumps during cold weather, a significant worldwide factor.

Together, these factors determine not only the quality of the formed sulphur but also the ease with which it can be handled and the potential impact on the environment during storage and transportation (formed sulphur can be handled as many as 15 times between solidification and subsequent reprocessing).

We have therefore focused the design and development (in collaboration with Sandvik sulphur forming equipment) – as well as our complete array of downstream handling equipment – on ensuring that SUDIC premium quality sulphur reaches the end user.

SUDIC SPECIFICATIONS

According to the SUDIC definition, premium quality sulphur will meet the following specifications 21 days after forming:

Mean size:

between 2 and 5 mm

Size distribution:

less than 5 % bigger than 4,75 mm

minimum 75 % between 4,4 and 2,4 mm

less than 2 % smaller than 1,18 mm

less than 0,1 % smaller than 0,3 mm

Moisture:

less than 0,5 % by weight

Friability:

less than 1 % fines (< 0,3 mm) under stress level I

less than 2 % fines (< 0,3 mm) under stress level II

Bulk density:

1040 kg/m3 loose, 1200 kg/m3 agitated

Angle of repose:

not less than 25°

Compaction:

below 0,2 % fines by weight (< 0.3 mm) under static load

below 0,5 % fines by weight (< 0.3 mm) under dynamic load

Sandvik forming equipment meets or exceeds these specifications.